That your company has an in-house software dev team is impressive. Does the revenue-generating business have access to that team?

Not OP, but in a similar situation. We have in-house dev for both tooling/infrastructure as well as revenue generation. For better or worse, leaders have neglected the software tooling and infrastructure that we use to build and deliver our revenue generating software for decades. Some serious cracks in the foundation showing and we might finally start fixing things.

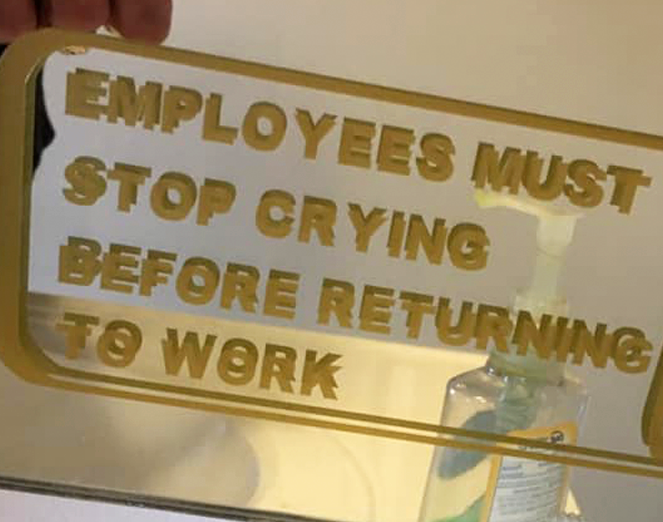

Great read, with some amusing asides.

Shots fired!